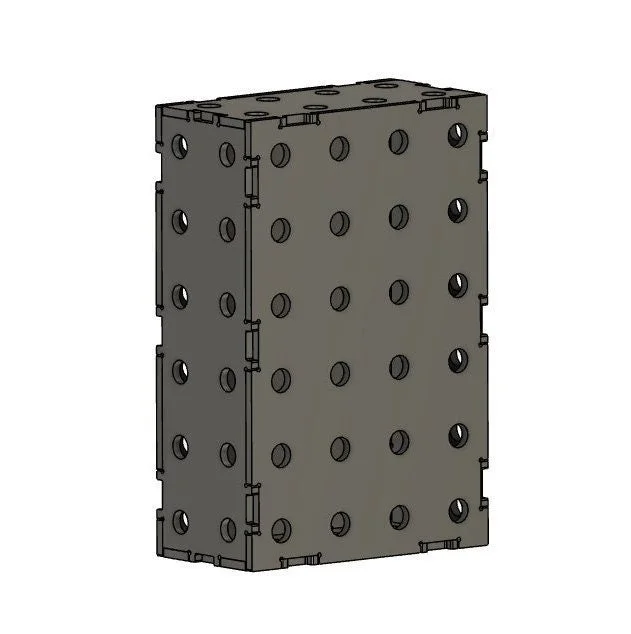

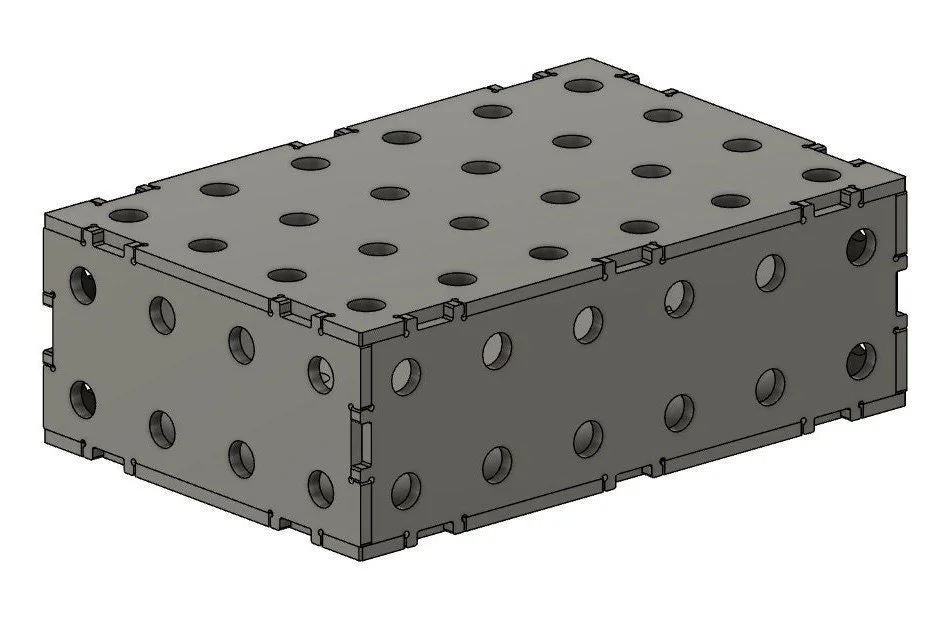

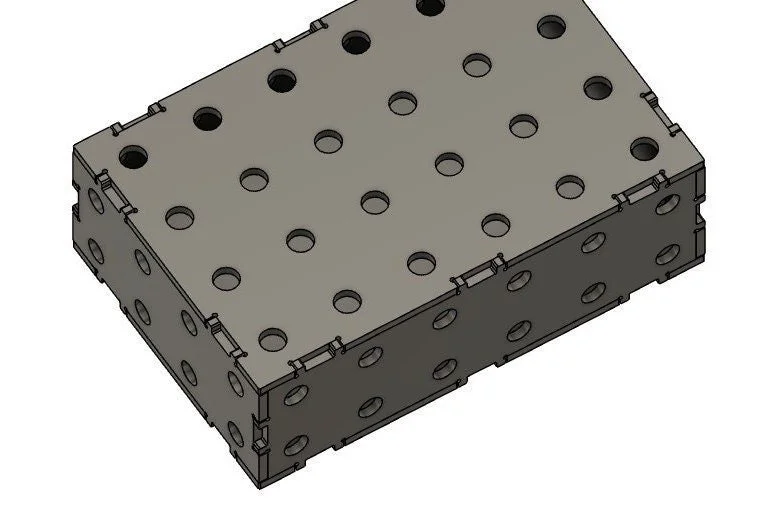

Fab Block 300 x 200 x 100 6mm

Fab Block 300 x 200 x 100 6mm

$7.50

Downloadable DXF files ONLY. Metric Measurements

Cut or send to a CNC Laser/water jet cutter for profile cutting all the parts needed to construct a precision welding / fixturing squares.

I would recommend against CNC plasma cutting as results with small 16 round holes are usually subpar and for best result using cambering clamps / pins and other fixture table components you want precision holes.

Allows for clamping just about anywhere on a fixture table or clamping materials independent of a fixture table.

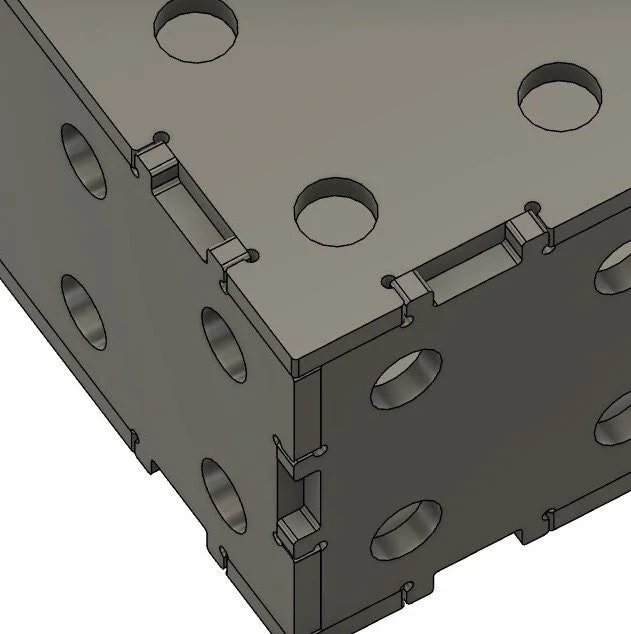

Slot and tab design. simple and easy assembly.

Quick hot tack in the designated slot is all you needed. it will mostly hold itself together.

No need for excessive welding you will only risk distortion.

Take your time to make sure the components are firmly in place before tacking for best results.

Worst case if you make an error assembling them they can be faced on in a mill to ensure flatness and true 90.

Supply your own files to be laser cut and get as many as you may need.

Must be cut from 6mm plate for the slot and tab design to work.

I have allowed 0.2mm clearance between slots and tabs. Clearance should not be an issue most lasers will cut within that tolerance, worst case the edges might need a light touch with a file just enough to knock into place, tight fitment will ensure easier and more accurate assembly.

Thanks.

Cut or send to a CNC Laser/water jet cutter for profile cutting all the parts needed to construct a precision welding / fixturing squares.

I would recommend against CNC plasma cutting as results with small 16 round holes are usually subpar and for best result using cambering clamps / pins and other fixture table components you want precision holes.

Allows for clamping just about anywhere on a fixture table or clamping materials independent of a fixture table.

Slot and tab design. simple and easy assembly.

Quick hot tack in the designated slot is all you needed. it will mostly hold itself together.

No need for excessive welding you will only risk distortion.

Take your time to make sure the components are firmly in place before tacking for best results.

Worst case if you make an error assembling them they can be faced on in a mill to ensure flatness and true 90.

Supply your own files to be laser cut and get as many as you may need.

Must be cut from 6mm plate for the slot and tab design to work.

I have allowed 0.2mm clearance between slots and tabs. Clearance should not be an issue most lasers will cut within that tolerance, worst case the edges might need a light touch with a file just enough to knock into place, tight fitment will ensure easier and more accurate assembly.

Thanks.